Choosing the right metal lathe is crucial for achieving precise and efficient results, whether you’re a seasoned machinist or a hobbyist. To make an informed decision, consider the size and complexity of your projects, as well as the lathe’s dimensions, capabilities, and features like variable speed settings and durable construction. Selecting a lathe that aligns with your specific needs will save you time and money while ensuring top-quality work.

Understanding the Basics of Metal Lathes

When selecting a metal lathe, it’s crucial to understand the different types available and the key components that make up these machines. Familiarize yourself with these fundamentals to make a more informed decision.

Types of Metal Lathes

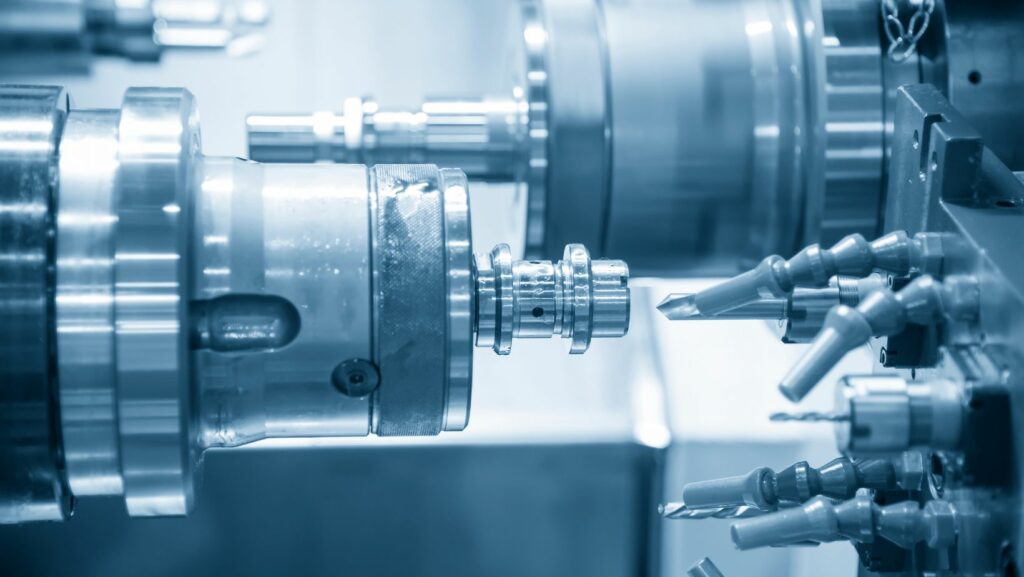

Metal lathes come in various types, each suited for specific tasks or levels of expertise. Engine lathes are versatile and commonly used due to their wide range of capabilities. Turret lathes are ideal for repetitive production tasks, featuring multiple tool holders to reduce setup time.

CNC lathes utilize computer controls for high precision and automation, often found in professional settings. Bench lathes are smaller and perfect for hobbyists or small shops. Understanding which type aligns with your needs can greatly influence your productivity and project quality.

Key Components and Functions

Knowing the key components of a metal lathe will help you use the machine more effectively. The headstock houses the main spindle and speed control mechanisms. Tailstock supports the workpiece and can hold tools for drilling operations.

The carriage moves along the bed and holds the cutting tools, enabling precise cuts. The bed is the base of the lathe, providing stability and precision. Familiarize yourself with the apron, as it controls the carriage’s movement, and the cross-slide, which allows for cutting along multiple axes.

Ensure you’re aware of these components to maximize the lathe’s functionality and output quality.

Identifying Your Machining Needs

Before purchasing a metal lathe, it’s essential to understand your specific machining requirements. Key factors include the types of materials you will be working with, the size and power needed for your projects, and the precision and tolerances your work demands.

Assessing Material Types

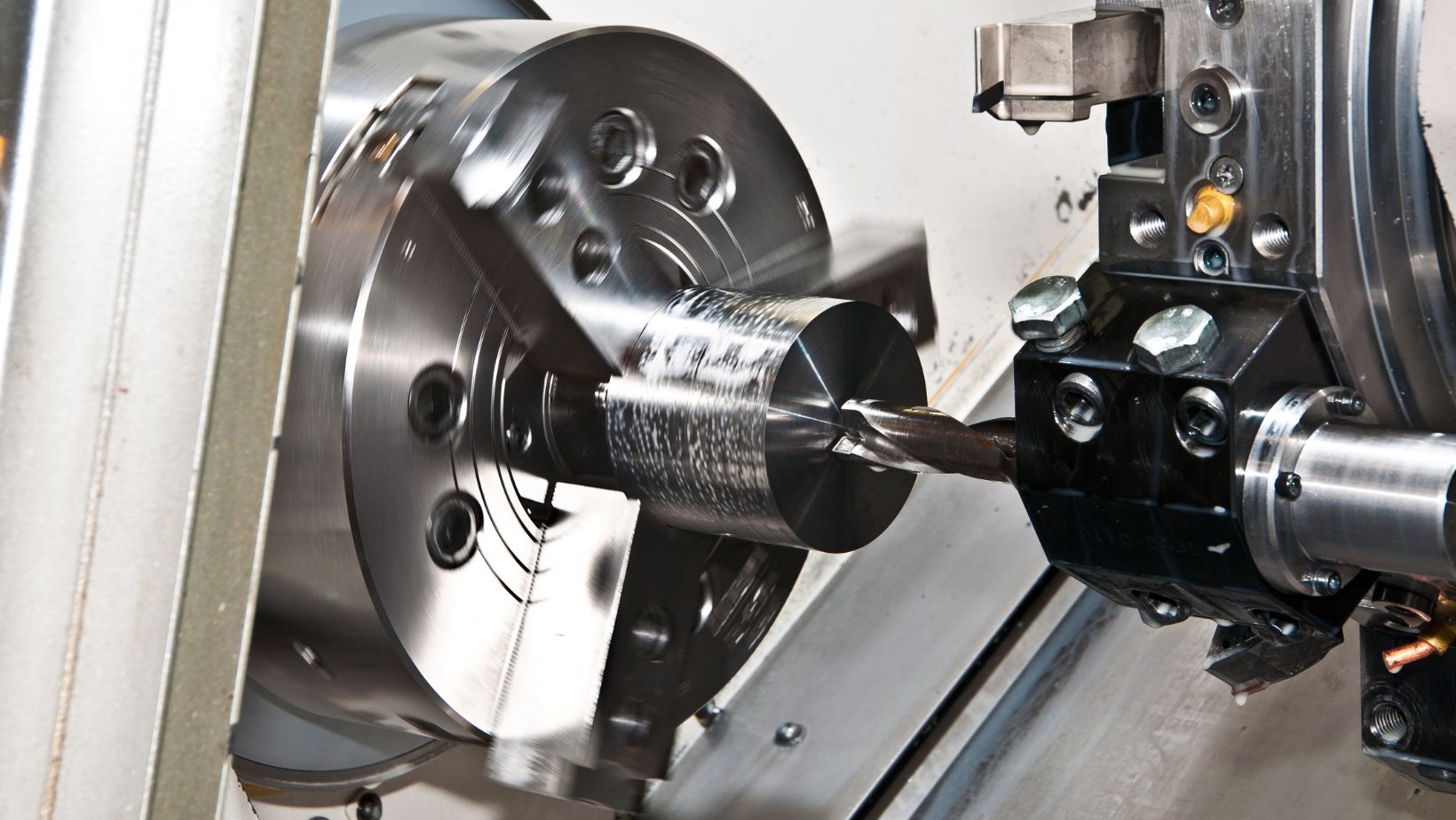

First, consider the types of metal you will be machining. Different metals require different lathe capabilities. Soft metals like aluminum and brass are easier to machine and don’t demand as much power. Harder metals like steel or titanium will need a lathe with more power and durability.

Using a lathe that isn’t suited for your material can lead to poor results and equipment damage. Check the lathe’s specifications to ensure it can handle the metals you plan to work with regularly.

Determining Size and Power Requirements

Next, assess the size of the projects you’ll undertake. Bench lathes are compact and suitable for smaller parts but may lack the power for more extensive work. Engine lathes are more robust and versatile, suited for a range of project sizes.

Consider the lathe’s power, usually measured in horsepower (HP). More horsepower allows you to work with harder metals and larger pieces. Choose a lathe that matches the scale of your projects to avoid overtaxing the machine.

Precision and Tolerance Levels

Finally, think about the precision you need. Tighter tolerances are crucial for intricate and high-precision work. Look for lathes with high spindle accuracy and precision control features.

Digital readouts (DRO) and finely adjustable components help achieve precision. If your projects demand extreme accuracy, ensure the lathe specifications include tolerance levels that meet your requirements.

Investing in a machine that aligns with your precision needs ensures quality and consistency in your work.

Features to Look For in a Metal Lathe

When selecting a metal lathe, you will want to consider advanced control features and prioritize safety and maintenance aspects. Each feature can significantly enhance your efficiency and safety during operation.

Advanced Control Features

Modern metal lathes often come with advanced control features that simplify complex tasks. Look for models with digital readouts (DROs), which provide precise measurements and ease of use. DROs can greatly improve accuracy, especially for intricate work.

Furthermore, consider machines with variable speed controls. Being able to adjust the speed allows you to work with different materials more effectively. Programmable spindle speeds and feeds also help in maintaining consistency and reducing manual errors.

Another vital feature is CNC capabilities. Computer Numerical Control (CNC) systems automate many functions, allowing you to perform repetitive tasks with high precision. If you’re working on complex, high-volume projects, CNC is a game-changer.

Safety and Maintenance

Safety should always be a top priority when operating a metal lathe. Check for features such as emergency stop buttons, which can immediately halt operations if something goes wrong. Safety interlocks that prevent the machine from operating under unsafe conditions are also essential.

Regular maintenance keeps your lathe in optimal condition. Choosing a model with easy-to-access oil reservoirs and lubrication points can save you a lot of time and effort. Look for machines that require minimal manual lubrication to lessen maintenance tasks.

Additionally, chip guards and splash guards are practical features to keep metal shavings and fluids contained, ensuring a cleaner and safer working environment. Durable and robust warranties can also provide peace of mind, as they cover unexpected repairs or parts replacement.

Making the Purchase

Selecting the right metal lathe involves ensuring you stay within your budget, getting a good warranty and support, and choosing a reputable brand based on evaluations and reviews.

Budget Considerations

Setting a budget is your first step. Metal lathes can range from a few hundred dollars to several thousand. Think about what features are non-negotiable and what you can compromise on. Quality often corresponds with price, but there are affordable options that still offer excellent performance.

Consider additional costs such as accessories and maintenance. Tooling and attachments can add up quickly, so factor these into your budget. Look for packages that include essential tools to save money.

Key points:

- Determine your budget range

- Factor in additional costs like tooling and maintenance

- Look for packages that offer essential tools

Warranty and Support

A good warranty provides peace of mind. Check the length and coverage of the warranty before purchasing. Look for warranties that cover both parts and labor.

Customer support is equally important. Ensure the manufacturer offers reliable and accessible support. Read reviews or ask for recommendations to gauge the quality of support services.

Buying from established brands often means better warranty and support services. American made lathes are a solid option due to their robust warranties and support systems.

Key points:

- Check warranty length and coverage

- Ensure good customer support availability

- Established brands often offer better warranties

Evaluating Brands and Evaluations

Researching brands is crucial. Look for manufacturers with a long history in the industry. Brands with well-regarded reputations often put out reliable and durable machines.

User reviews provide insights into the real-world performance of a lathe. Pay attention to reviews that mention long-term functionality and reliability. Be cautious of reviews that seem overly negative or positive without detailed explanations.

Checking for specific features mentioned by reviewers can help you decide if a particular model meets your needs. Reviews can reveal common issues or exceptional benefits.

Key points:

- Research well-established brands

- Read user reviews for real-world insights

- Look for reviews detailing specific features

In Conclusion

Selecting the right metal lathe requires careful consideration of your project needs, budget, and desired features. By understanding the types of lathes available, evaluating essential components, and choosing a reputable brand with solid warranties and support, you can ensure your investment leads to precise and efficient results, ultimately enhancing the quality of your work.